| Model: | Metal cutting lathe |

|---|---|

| Category: | CNC-Machines |

Worm thread grinding machines are specialized types of equipment that play a critical role in various industries. They are primarily used to create precise worm gear threads. This article explores what industries most commonly use worm thread grinding machines and why they are essential in these sectors.

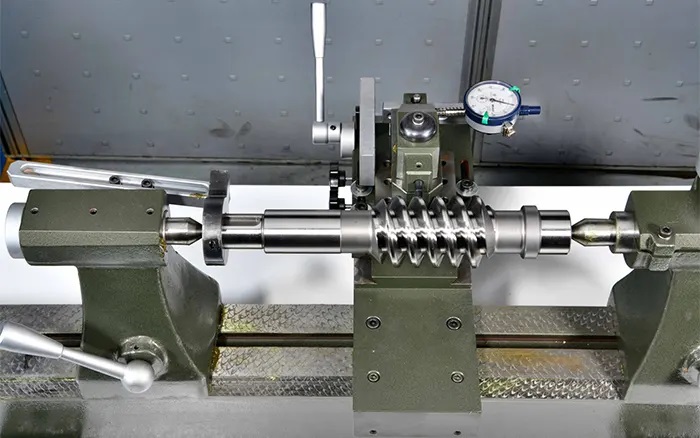

The Structure of a Worm Thread Grinding Machine

Before delving into its applications, it’s crucial to understand the structure of a worm thread grinding machine. The machine typically includes a grinding wheel, workpiece, and a dressing device. The grinding wheel is responsible for the actual grinding process, while the workpiece is the item being worked on. The dressing device, on the other hand, helps maintain the shape and sharpness of the grinding wheel.

Working Principle of a Worm Thread Grinding Machine

The worm thread grinding machine operates based on a simple yet efficient principle. It uses a grinding wheel to create threads on a workpiece. The workpiece is clamped, and the grinding wheel rotates at high speed, grinding away material to create the desired thread.

Common Applications of Worm Thread Grinding Machines

Product Description Forming machine for construction and large metal structures...

DESCRIPTION Table size 2200 x 1000 mm Byu3Fq8Cur Longitudinal travel 2050 mm...

Product Description Main performance characteristics: Hydraulic transmissi...